Produits

Produits phares

Un système hautement fiable qui ne nécessite aucun temps d'arrêt pour l'entretien et coûte moins cher à exploiter.

Nos échangeurs de chaleur conviennent au refroidissement des fluides des concentrateurs solaires, au refroidissement de la génération d'hydrogène, au refroidissement combiné de la chaleur et de l'électricité, au chargement du bus par induction sans fil, au refroidissement de la puissance de pointe auxiliaire, au refroidissement et au refroidissement combinés par cycle de Rankine organique.

Overview

Heat exchangers are widely used in power industry. High efficiency heat exchangers can reduce energy consumption and achieve the purpose of energy-saving and emission-reduction.

Therefore, heat exchangers are widely used in the waste heat recovery of flue gas in power plant.

At present, the heat exchangers for the waste heat recovery mainly include dry coolers, GGH heat exchangers, etc.

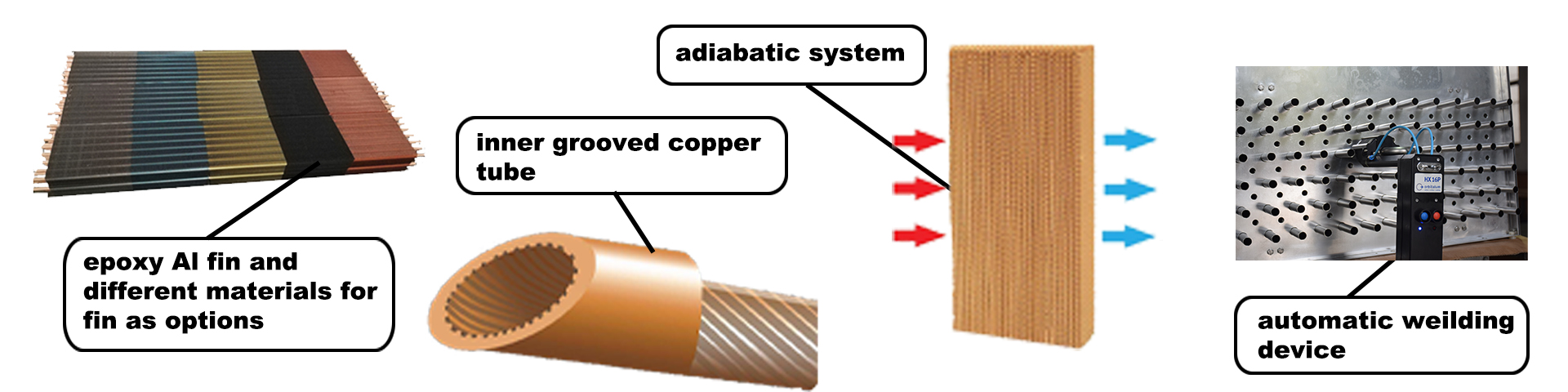

We have epoxy Al fin, inner grooved copper tube, flange, adiabatic system and EC/AC fans custom engineered for various end use conditions and geographies.

And to guarantee the product quality, we use full-automatic wielding device and automatic spray equipment from Germany in our processing line.

Features

1. High efficient heat exchanger

Reasonable design reduces fan loss while obtaining heat exchange.

Reasonable copper tube design reduces the pressure drop in the coil.

2. Reasonable fan selection

Select AC/EC fans with low energy consumption.

Increase air fluidity and reduce noise.

3. Various materials for tubes and fins as options

Applicable in different industries for power plant, industrial HVAC, pharmaceutical factory, etc.

Applications